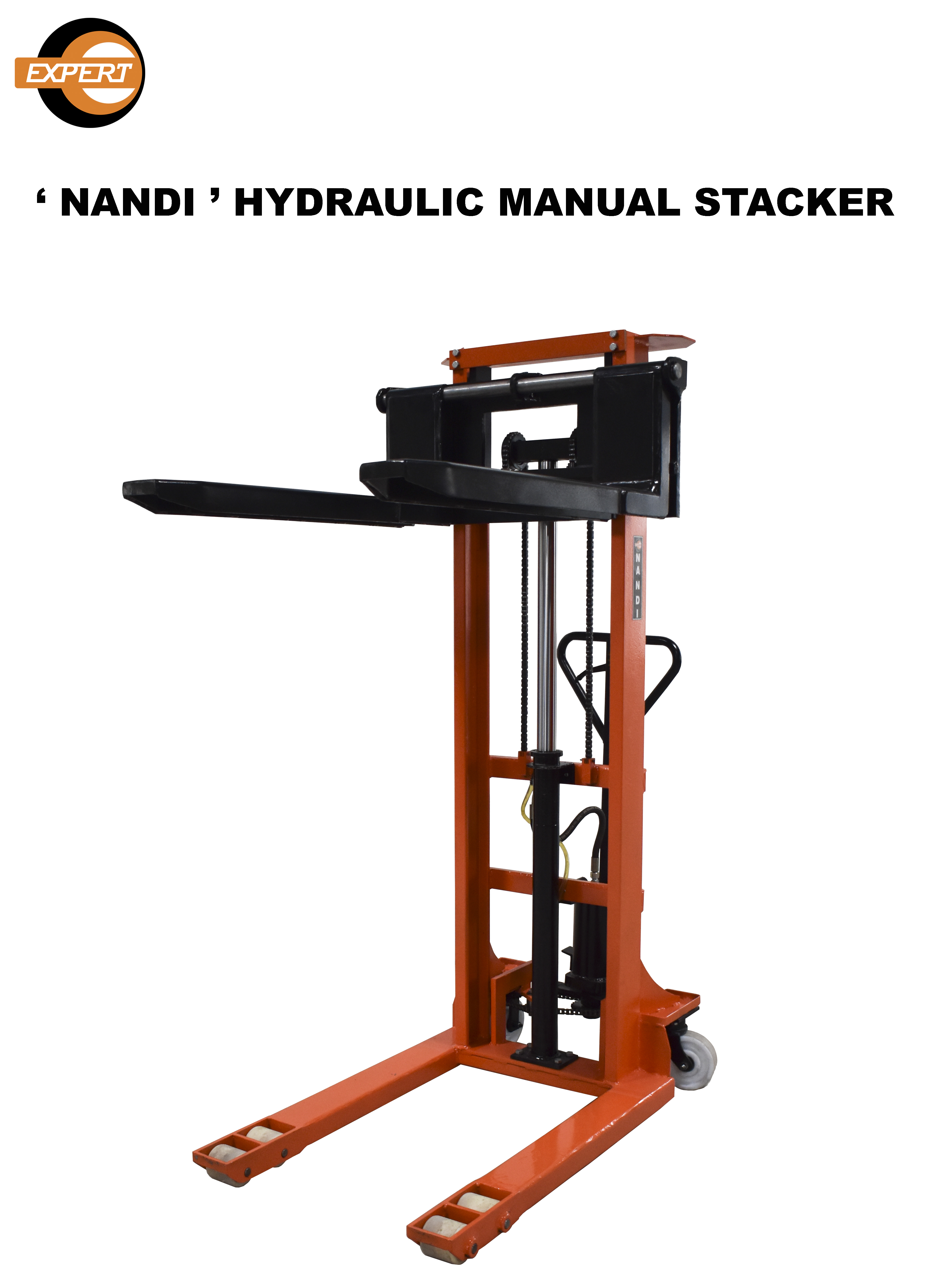

Karur ' Nandi ' Hydraulic Manual Stacker

Price 78000 INR/ Number

Karur ' Nandi ' Hydraulic Manual Stacker Specification

- Lifting Speed

- Manual, depends on operator

- Forklift

- No

- Rotation Type

- Fixed

- Handle Type

- Ergonomic handle for easy maneuvering

- Control System

- Manual by handle pump

- Wheel Type

- PU Wheels

- Features

- Hydraulic lifting mechanism, safety screen

- Equipment Type

- Stacker

- Condition

- New

- Lifting Capacity

- 1000 Kg

- Max. Lifting Load

- 1000 Kg

- Max. Lifting Height

- 1600 mm

- Power Source

- Manual

- Feature

- Easy to operate, durable construction

- Attributes

- Robust design, manually operated

About Karur ' Nandi ' Hydraulic Manual Stacker

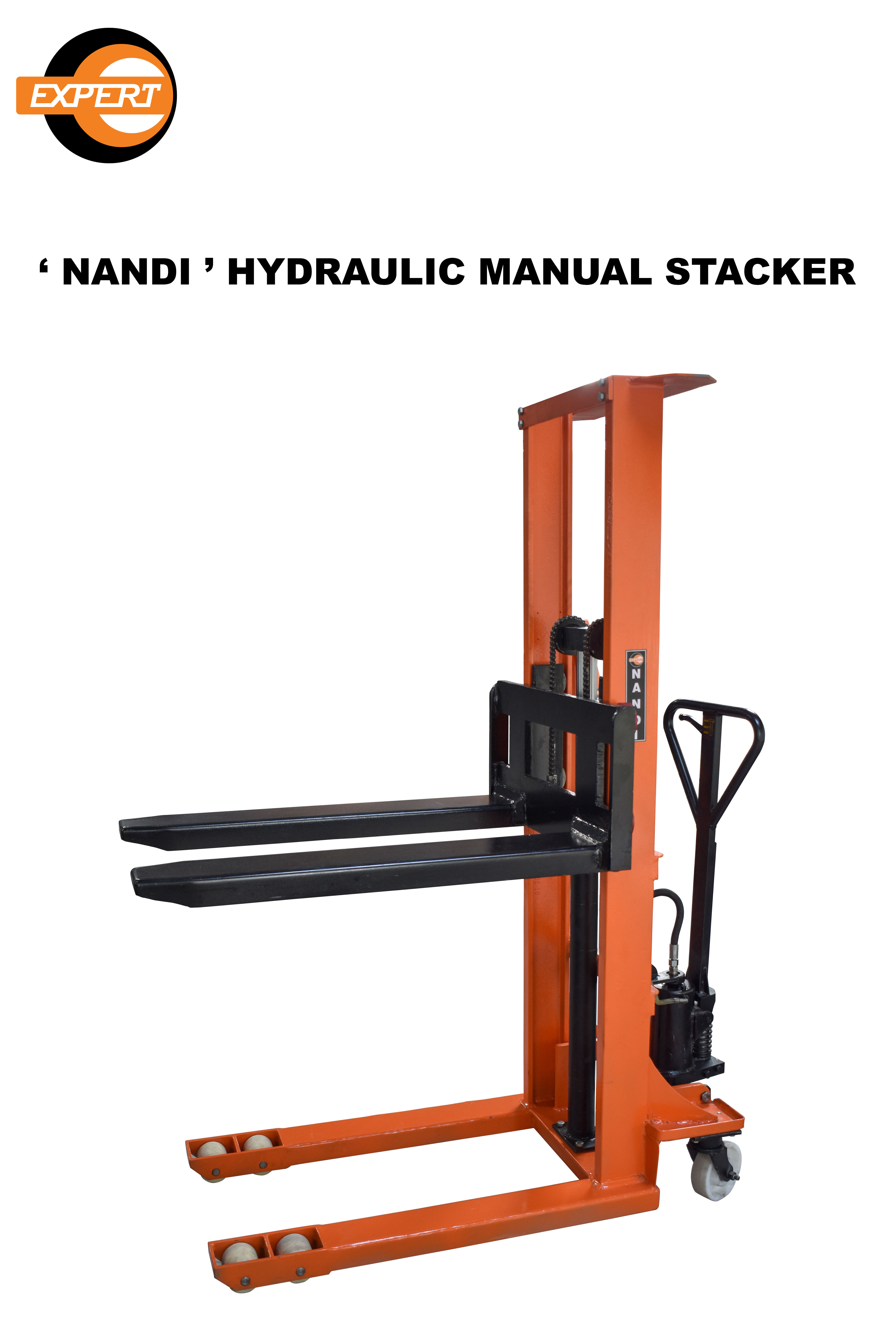

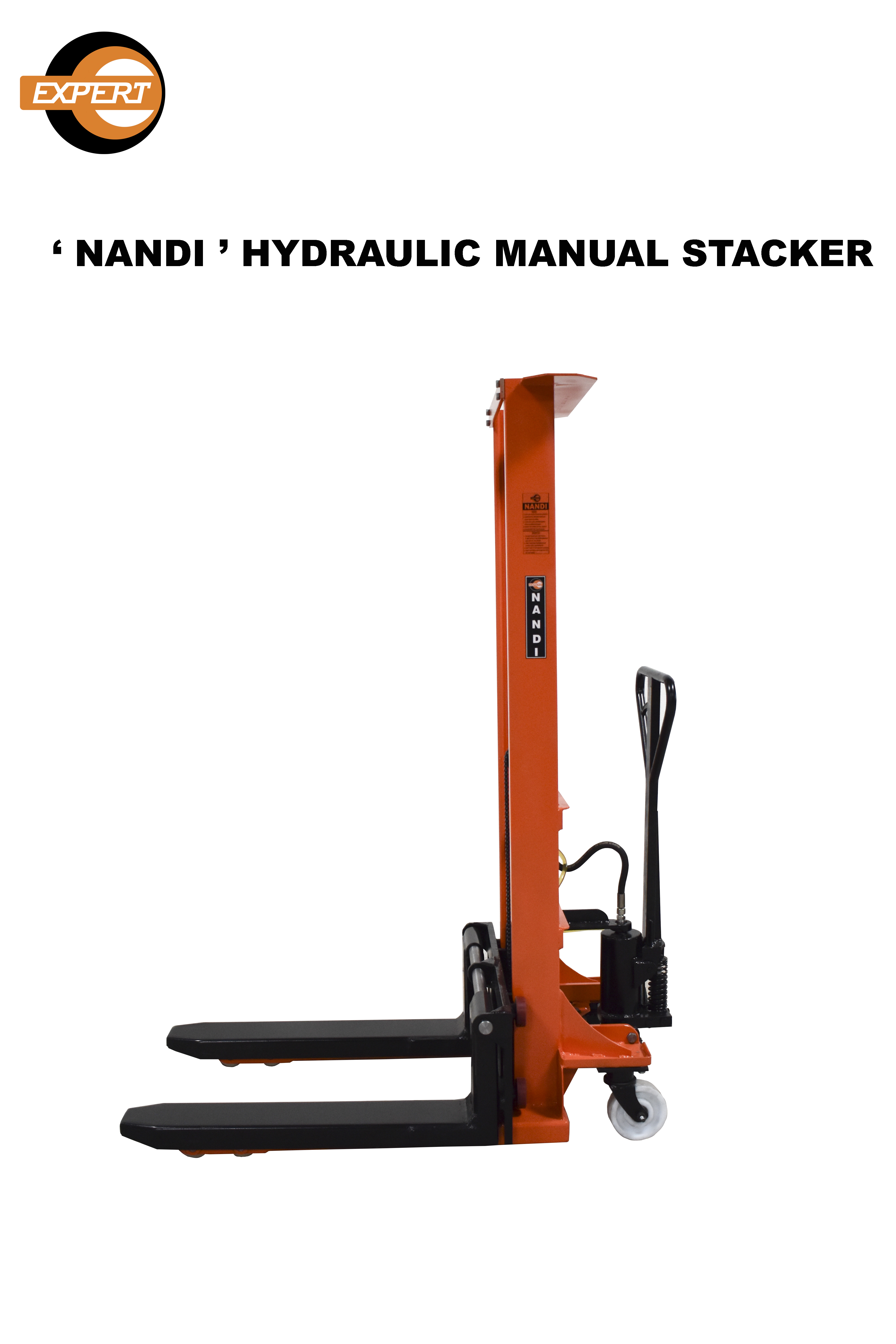

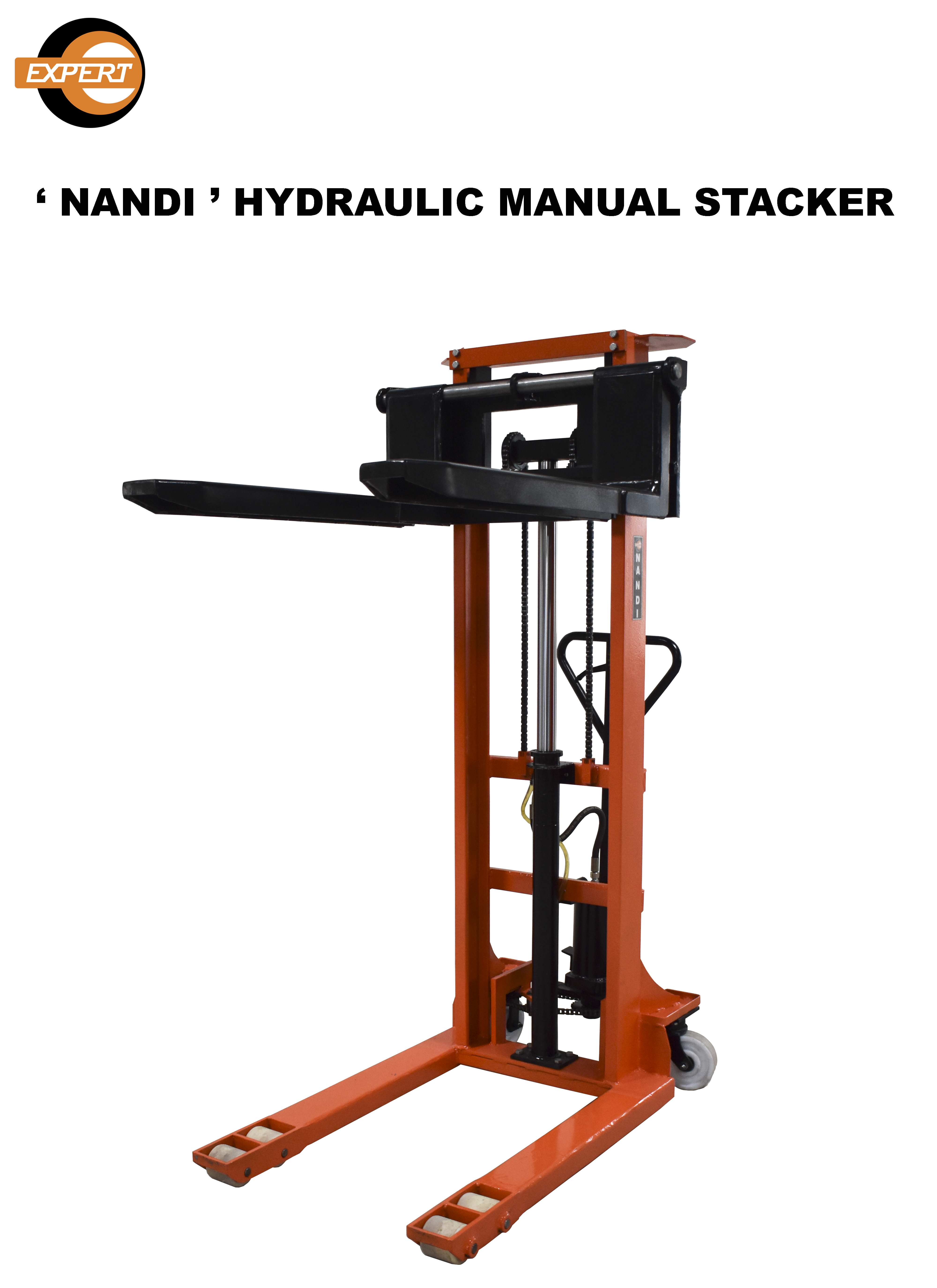

We are one of the manufacturers and suppliers of a hydraulic manual stacker. This product is manufactured using best quality material. The length, width and height of the stacker can be manufactured according to customer requirement. Nandi hydraulic manual stacker comes with a standard configuration of 250 kgs, 500 kgs, 1000 kgs, 1500 kgs, 2000 kgs rated capacity. Adjustable forks, fixed forks and platform type are the three variants available in the product.

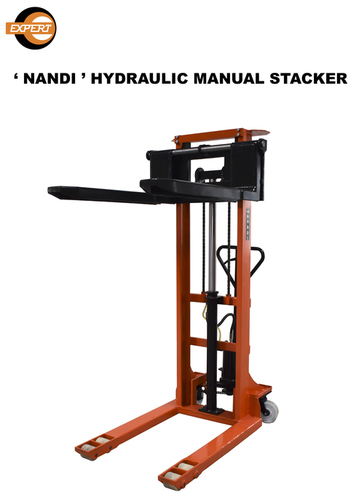

Heavy-Duty Performance and Flexible Usage

Engineered for demanding warehouse, loading, and unloading requirements, the Karur Nandi stacker boasts a robust steel construction. Its adjustable forks and ergonomic design cater to diverse materials and pallet sizes, ensuring compatibility with evolving operational needs.

Enhanced Safety Features and Easy Operation

The hydraulic manual stacker comes equipped with a safety screen and a manual handle pump system, minimizing risks during usage. Its ergonomic handle and PU wheels enhance operator comfort, while the manual control allows precise lifting and placement.

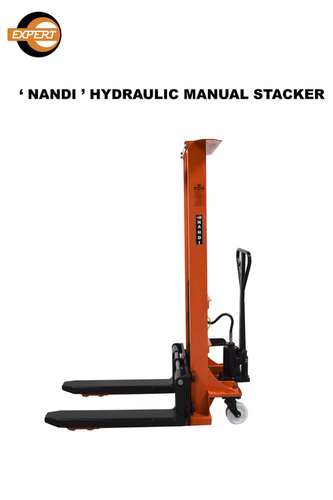

Durability and Low Maintenance

Featuring a durable build and quality materials, this stacker is manufactured for longevity and low upkeep. The manual hydraulic mechanism reduces dependency on power sources, ensuring consistent performance with minimal maintenance interventions.

FAQs of Karur Nandi Hydraulic Manual Stacker:

Q: How do I operate the Karur Nandi Hydraulic Manual Stacker?

A: To operate the stacker, use the ergonomic handle to maneuver the device into position. Employ the manual hydraulic pump via the control handle to lift and lower loads. The movement and lifting speed depend on the operators manual input for complete control.Q: What types of loads and applications is this stacker suitable for?

A: The stacker is ideal for handling pallets, crates, and various materials up to 1000 kg in warehouses, loading docks, and industrial settings. Its adjustable forks and maximum lifting height of 1600 mm provide flexibility for multiple material handling applications.Q: When is maintenance required for the manual hydraulic stacker?

A: Routine inspections are recommended after regular use, focusing on the hydraulic pump, wheels, and forks. Scheduled maintenance involves checking for fluid leaks, lubricating moving parts, and ensuring that all safety features function optimally.Q: Where can I use this hydraulic manual stacker effectively?

A: This stacker performs best in indoor environments such as warehouses, manufacturing floors, and loading/unloading areas where manual, self-powered equipment enhances safety and efficiency without reliance on electric or fuel power.Q: What is the process for adjusting the fork width?

A: The fork width can be easily adjusted from 330 mm to 740 mm to accommodate various pallet sizes. Simply release the securing mechanism, slide the forks to the desired width, and securely lock them in place before lifting any load.Q: What are the primary benefits of using a manual hydraulic stacker?

A: Manual hydraulic stackers offer energy efficiency, dependable lifting capability, low maintenance costs, and enhanced control during operation. Their robust design ensures longevity, making them ideal for consistent daily use in demanding environments.

More Products in HYDRAULIC MANUAL STACKER Category

Theni ' Nandi ' Hydraulic Manual Stacker

Price 78000 INR / Number

Minimum Order Quantity : 1 Number

Color : Orange

Weight : 250 Kilograms (kg)

Product Type : Material Handling

Lifting Capacity : 250 kgs, 500 kgs, 1000 kgs, 1500 kgs, 2000 kgs

Tiruppur ' Nandi ' Hydraulic Manual Stacker

Price 78000 INR / Number

Minimum Order Quantity : 1 Number

Color : Orange

Weight : 250

Product Type : Material Handling

Lifting Capacity : 250 kgs, 500 kgs, 1000 kgs, 1500 kgs, 2000 kgs

Dindigul ' Nandi ' Hydraulic Manual Stacker

Price 78000 INR / Number

Minimum Order Quantity : 1 Number

Color : Orange

Weight : 250

Product Type : Material Handling

Lifting Capacity : kgs, 500 kgs, 1000 kgs, 1500 kgs, 2000 kgs

Nagercoil ' Nandi ' Hydraulic Manual Stacker

Price 78000 INR / Number

Minimum Order Quantity : 1 Number

Color : Orange

Weight : 250 Kilograms (kg)

Product Type : Material Handling

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS